SDA Series aluminum alloy acting thin type pneumatic standard compact air cylinder

Product Description

The cylinder is of thin design and small overall dimensions, which is suitable for occasions with limited space. Its working pressure is usually between 0.1~0.9mpa, which has high working efficiency.

SDA series cylinders have reliable sealing performance and smooth movement characteristics. It adopts high-precision manufacturing technology to ensure the tightness and accuracy of the cylinder. At the same time, the cylinder is equipped with a buffer device, which can reduce the impact and noise during movement.

Technical Specification

|

Bore Size(mm) |

12 |

16 |

20 |

25 |

32 |

40 |

50 |

63 |

80 |

100 |

|

Acting Mode |

Double Acting |

|||||||||

|

Working Media |

Cleaned Air |

|||||||||

|

Working Pressure |

0.1~0.9Mpa(kg/cm) |

|||||||||

|

Proof Pressure |

1.35Mpa(13.5kgf/cm) |

|||||||||

|

Working Temperature |

-5~70℃ |

|||||||||

|

Buffering Mode |

With |

|||||||||

|

Port Size |

M5 |

1/8 |

1/4 |

3/8 |

||||||

|

Body Material |

Aluminum Alloy |

|||||||||

|

Sensor Switch |

CS1-J |

CS1-G CS1-J |

||||||||

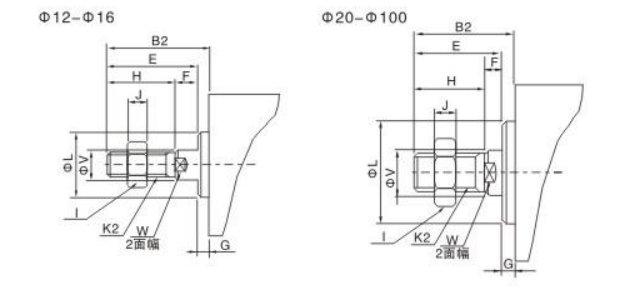

Description;SDA100teeth or 25in the cylinder piston rod, and the teeth for Ф 32 piston rod

100≤ST<150, and no magnetic, cylinder length 10.

ST≥150, no matter with or without magnetic, cylinder length 10.

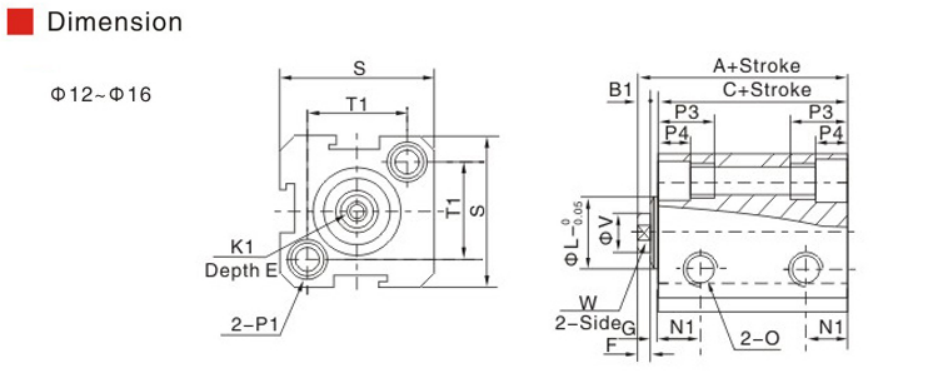

|

Bore Size(mm) |

Standard Type |

Magnet Type |

D |

B1 |

E |

F |

G |

K1 |

L |

N1 |

N2 |

O |

||

|

A |

C |

A |

C |

|||||||||||

|

12 |

22 |

17 |

32 |

27 |

/ |

5 |

6 |

4 |

/ |

M3X0.5 |

/ |

7.5 |

5 |

M5X0.8 |

|

16 |

24 |

18.5 |

34 |

28.5 |

/ |

5.5 |

6 |

4 |

1.5 |

M3X0.5 |

11 |

8 |

5.5 |

M5X0.8 |

|

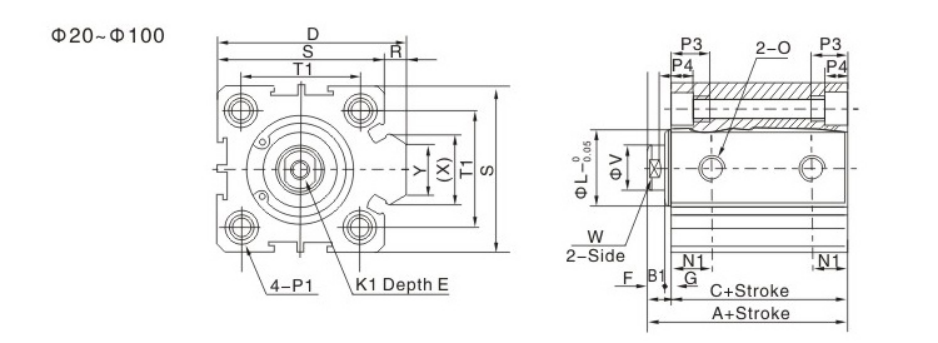

20 |

25 |

19.5 |

35 |

29.5 |

36 |

5.5 |

8 |

4 |

1.5 |

M4X0.7 |

14 |

9 |

5.5 |

M5X0.8 |

|

25 |

27 |

21 |

37 |

31 |

42 |

6 |

10 |

4 |

2 |

M5X0.8 |

17 |

9 |

5.5 |

M5X0.8 |

|

32 |

31.5 |

24.5 |

41.5 |

34.5 |

50 |

7 |

12 |

4 |

3 |

M6X1 |

22 |

9 |

9 |

G1/8 |

|

40 |

33 |

26 |

43 |

36 |

58.5 |

7 |

12 |

4 |

3 |

M8X1.25 |

28 |

9.5 |

7.5 |

G1/8 |

|

50 |

37 |

28 |

47 |

38 |

71.5 |

9 |

15 |

5 |

4 |

M10X1.5 |

38 |

10.5 |

10.5 |

G1/4 |

|

63 |

41 |

32 |

51 |

42 |

84.5 |

9 |

15 |

5 |

4 |

M10X1.5 |

40 |

12 |

11 |

G1/4 |

|

80 |

52 |

41 |

62 |

51 |

104 |

11 |

20 |

6 |

5 |

M14X1.5 |

45 |

14.5 |

14.5 |

G3/8 |

|

100 |

63 |

51 |

73 |

61 |

124 |

12 |

20 |

7 |

5 |

M18X1.5 |

55 |

17 |

17 |

G3/8 |

|

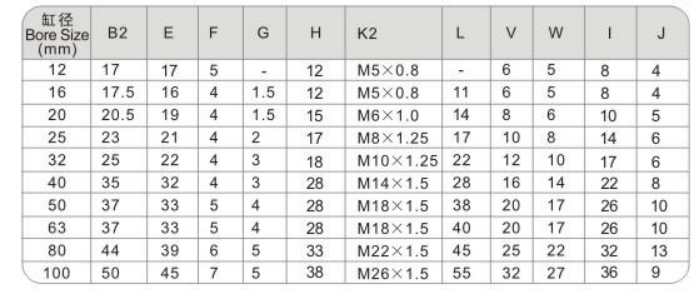

Bore Size(mm) |

P1 |

|

12 |

Double side: Ф6.5 ThreadM5*0.8 Through hole Ф4.2 |

|

16 |

Double side: Ф6.5 ThreadM5*0.8 Through hole Ф4.2 |

|

20 |

Double side:Ф 6.5 ThreadM5*0.8 Through hole Ф4.2 |

|

25 |

Double side:Ф 8.2 ThreadM6*1.0 Through hole Ф4.6 |

|

32 |

Double side:Ф 8.2 ThreadM6*1.0 Through hole Ф4.6 |

|

40 |

Double side: Ф10 ThreadM6*1.25 Through hole Ф6.5 |

|

50 |

Double side: Ф11 ThreadM6*1.25 Through hole Ф6.5 |

|

63 |

Double side: Ф11 ThreadM8*1.25 Through hole Ф6.5 |

|

80 |

Double side: Ф14 ThreadM12*1.75 Through hole e:Ф9.2 |

|

100 |

Double side: Ф17.5 ThreadM14*12 Through hole Ф11.3 |

|

Bore Size(mm) |

P3 |

P4 |

R |

S |

T1 |

V |

W |

X |

Y |

|

12 |

12 |

4.5 |

/ |

25 |

16.2 |

6 |

5 |

/ |

/ |

|

16 |

12 |

4.5 |

/ |

29 |

19.8 |

6 |

5 |

/ |

/ |

|

20 |

14 |

4.5 |

2 |

34 |

24 |

8 |

6 |

11.3 |

10 |

|

25 |

15 |

5.5 |

2 |

40 |

28 |

10 |

8 |

12 |

10 |

|

32 |

16 |

5.5 |

6 |

44 |

34 |

12 |

10 |

18.3 |

15 |

|

40 |

20 |

7.5 |

6.5 |

52 |

40 |

16 |

15 |

21.3 |

16 |

|

50 |

25 |

8.5 |

9.5 |

62 |

48 |

20 |

17 |

30 |

20 |

|

63 |

25 |

8.5 |

9.5 |

75 |

60 |

20 |

17 |

28.7 |

20 |

|

80 |

25 |

10.5 |

10 |

94 |

74 |

25 |

22 |

36 |

26 |

|

100 |

30 |

13 |

10 |

114 |

90 |

25 |

22 |

35 |

26 |