SC Series aluminum alloy acting standard pneumatic air cylinder with port

Product Description

The working principle of SC series cylinders is to use the force of air pressure to push the piston to move in the cylinder. When air pressure is added to one port of the cylinder, the piston in the cylinder moves under pressure, thus pushing the mechanical device connected with the piston. By controlling the input and discharge of air pressure, bidirectional or unidirectional movement can be realized.

This type of cylinder can choose double acting or single acting mode according to the actual demand. In double acting mode, the cylinder can move forward and backward under the action of air pressure; In the single acting mode, the cylinder can only move under the pressure of one side, and the other side can reset the piston through the return force of the spring.

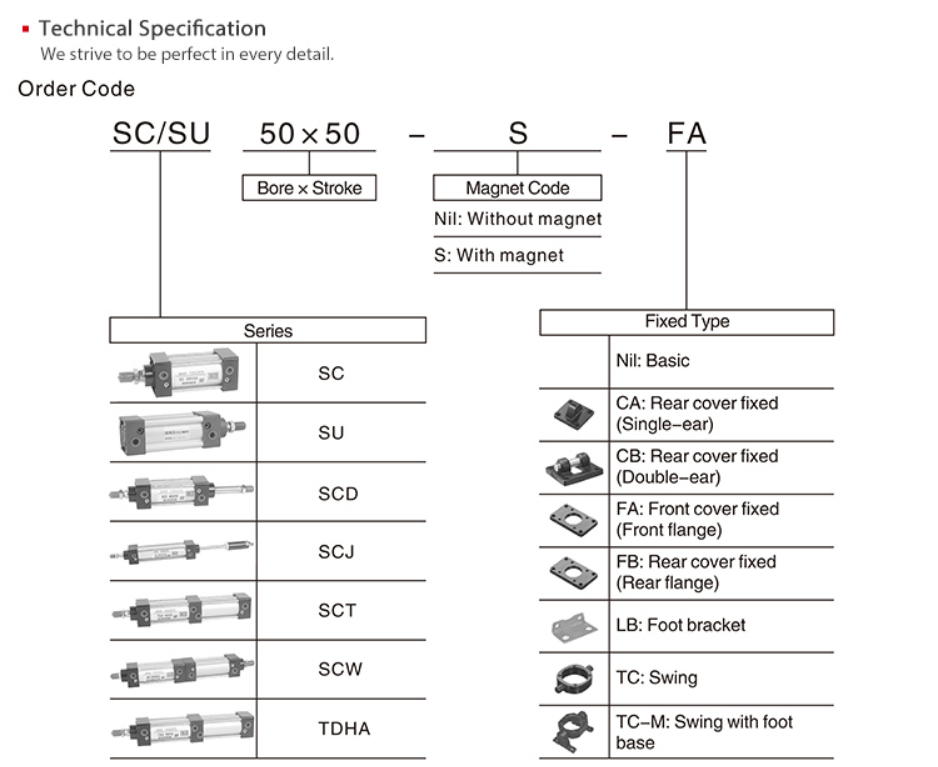

Technical Specification

|

Bore Size(mm) |

32 |

40 |

50 |

63 |

80 |

100 |

125 |

160 |

200 |

250 |

|

Acting Mode |

Double Acting |

|||||||||

|

Working Media |

Cleaned Air |

|||||||||

|

Working Pressure |

0.1~0.9Mpa(1~9kgf/cm2) |

|||||||||

|

Proof Pressure |

1.35MPa(13.5kgf/cm2) |

|||||||||

|

Working Temperature Range |

-5~70℃ |

|||||||||

|

Buffering Mode |

Adjustable |

|||||||||

|

Buffering distance(mm) |

13-18 |

22 |

25-30 |

|||||||

|

Port Size |

1/8 |

1/4 |

3/8 |

1/2 |

3/4 |

1 |

||||

|

Body Material |

Aluminum Alloy |

|||||||||

|

Sensor Switch |

CS1-F CS1-U SC1-G DMSG |

|||||||||

|

Fixed Base of Sensor Switch |

F-50 |

F-63 |

F-100 |

F-125 |

F-160 |

F-250 |

||||

Stroke Of Cylinder

|

Bore Size(mm) |

Standard Stroke(mm) |

Max. Stroke(mm) |

Allowable Stroke(mm) |

|||||||||

|

32 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1000 |

2000 |

|

40 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1200 |

2000 |

|

50 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1200 |

2000 |

|

63 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

80 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

100 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

125 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

160 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

200 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

250 |

25 |

50 |

75 |

100 |

125 |

150 |

175 |

200 |

250 |

300 |

1500 |

2000 |

|

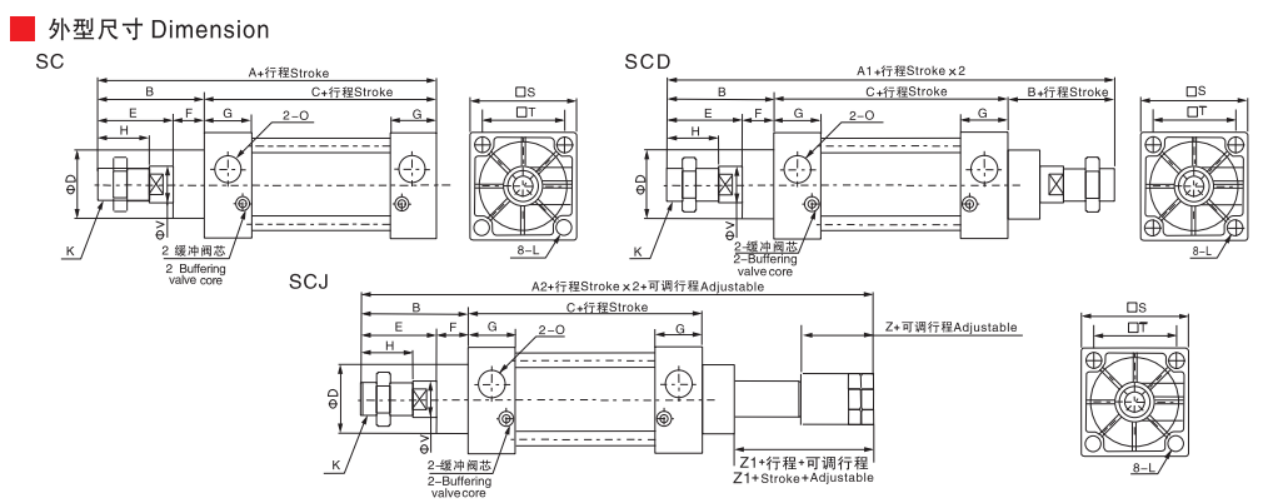

Bore Size(mm) |

A |

A1 |

A2 |

B |

C |

D |

E |

F |

G |

H |

K |

L |

O |

S |

T |

V |

|

32 |

140 |

187 |

185 |

47 |

93 |

28 |

32 |

15 |

27.5 |

22 |

M10x1.25 |

M6x1 |

G1/8 |

45 |

33 |

12 |

|

40 |

142 |

191 |

187 |

49 |

93 |

32 |

34 |

15 |

27.5 |

24 |

M12x1.25 |

M6x1 |

G1/4 |

50 |

37 |

16 |

|

50 |

150 |

207 |

197 |

57 |

93 |

38 |

42 |

15 |

27.5 |

32 |

M16x1.5 |

M6x1 |

G1/4 |

62 |

47 |

20 |

|

63 |

152 |

209 |

199 |

57 |

95 |

38 |

42 |

15 |

27.5 |

32 |

M16x1.5 |

M8x1.25 |

G3/8 |

75 |

56 |

20 |

|

80 |

183 |

258 |

242 |

75 |

108 |

47 |

54 |

21 |

33 |

40 |

M20x1.5 |

M10x1.5 |

G3/8 |

94 |

70 |

25 |

|

100 |

189 |

264 |

248 |

75 |

114 |

47 |

54 |

21 |

33 |

40 |

M20x1.5 |

M10x1.5 |

G1/2 |

112 |

84 |

25 |

|

125 |

245 |

345 |

312 |

100 |

145 |

60 |

68 |

32 |

40 |

54 |

M27x2 |

M12x1.75 |

G1/2 |

140 |

110 |

32 |

|

160 |

239 |

352 |

332 |

113 |

126 |

62 |

88 |

25 |

38 |

72 |

M36x2 |

M16x2 |

G3/4 |

174 |

134 |

40 |

|

200 |

244 |

362 |

342 |

118 |

126 |

62 |

88 |

30 |

38 |

72 |

M36x2 |

M16x2 |

G3/4 |

214 |

163 |

40 |

|

250 |

294 |

435 |

409 |

141 |

153 |

86 |

106 |

35 |

48 |

84 |

M42x2 |

M20x2.5 |

PT1 |

267 |

202 |

50 |

|

SQC125 |

245 |

345 |

312 |

100 |

145 |

60 |

68 |

32 |

40 |

54 |

M27x2 |

M12x1.75 |

G1/2 |

140 |

110 |

32 |