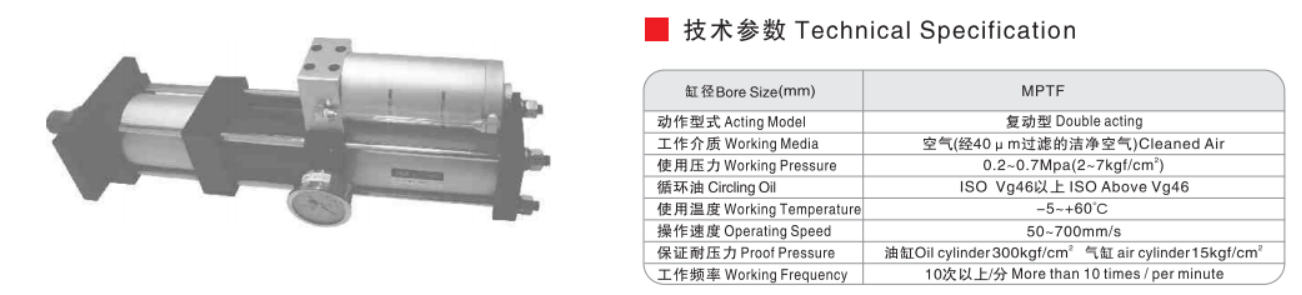

MPTF Series air and liquid booster type air cylinder with magnet

Product Description

The magnetic function of the MPTF series cylinder enables precise position control and detection with magnetic objects or sensors. This function is very useful in automation systems, which can achieve higher accuracy and reliability.

The cylinder adopts high-quality materials and advanced manufacturing processes to ensure its stability and durability. It has a compact design and is easy to install, suitable for various space limited applications.

The MPTF series cylinders are widely used in fields such as mechanical manufacturing, automotive industry, and packaging industry. They can be used to drive and control various equipment and mechanical components, providing efficient and reliable power support.

Technical Specification

|

Bore Size(mm) |

Tonnage T |

Overall stroke (mm) |

stroke (mm) |

Working pressure (kgf/cm²) |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

|

60 |

1 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

30 |

60 |

90 |

120 |

150 |

180 |

210 |

|

Booster output force Kg |

300 |

600 |

900 |

1250 |

1550 |

1850 |

2150 |

||||

|

Return pulling force Kg |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

||||

|

3 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

30 |

60 |

90 |

120 |

150 |

180 |

210 |

|

|

Booster output force Kg |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

3500 |

||||

|

Return pulling force Kg |

20 |

40 |

60 |

80 |

100 |

120 |

140 |

||||

|

80 |

5 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

|

Booster output force Kg |

1000 |

2000 |

3000 |

4000 |

5000 |

6000 |

7000 |

||||

|

Return pulling force Kg |

40 |

80 |

120 |

160 |

200 |

240 |

280 |

||||

|

100 |

10 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

78 |

156 |

234 |

312 |

390 |

468 |

546 |

|

Booster output force Kg |

1560 |

3120 |

4680 |

6240 |

7800 |

9360 |

10920 |

||||

|

Return pulling force Kg |

60 |

120 |

180 |

240 |

300 |

360 |

420 |

||||

|

13 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

78 |

156 |

234 |

312 |

390 |

468 |

546 |

|

|

Booster output force Kg |

1970 |

3940 |

5190 |

7880 |

9850 |

11820 |

13790 |

||||

|

Return pulling force Kg |

60 |

120 |

180 |

240 |

300 |

360 |

420 |

||||

|

125 |

15 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

120 |

240 |

360 |

480 |

600 |

720 |

840 |

|

Booster output force Kg |

2560 |

5120 |

7680 |

10240 |

12800 |

15350 |

17900 |

||||

|

Return pulling force Kg |

90 |

180 |

270 |

360 |

450 |

540 |

630 |

||||

|

20 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

120 |

240 |

360 |

480 |

600 |

720 |

840 |

|

|

Booster output force Kg |

3500 |

7000 |

10500 |

14000 |

17500 |

21000 |

24500 |

||||

|

Return pulling force Kg |

90 |

180 |

270 |

360 |

450 |

540 |

630 |

||||

|

30 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

120 |

240 |

360 |

480 |

600 |

720 |

840 |

|

|

Booster output force Kg |

4000 |

8000 |

12000 |

16000 |

20000 |

24000 |

28000 |

||||

|

Return pulling force Kg |

90 |

180 |

270 |

360 |

450 |

540 |

630 |

||||

|

160 |

40 |

50/100/150/200 |

5/10/15/20 |

Pre-pressing output force Kg |

200 |

400 |

600 |

800 |

1000 |

1200 |

1400 |

|

Booster output force Kg |

6500 |

13000 |

19500 |

26000 |

32500 |

39000 |

46000 |

||||

|

Return pulling force Kg |

165 |

330 |

495 |

660 |

825 |

990 |

1155 |

|

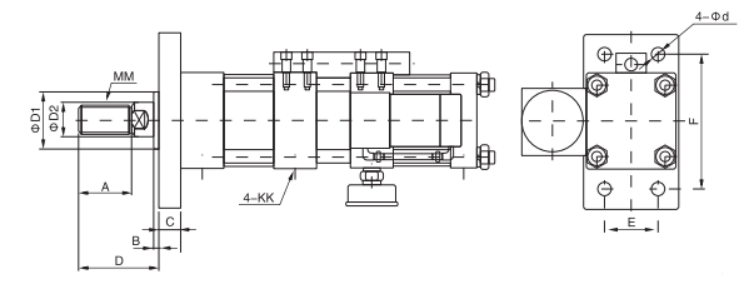

Tonnage |

A |

B |

C |

D |

D1 |

D2 |

E |

F |

d |

MM |

KK |

CC |

G |

H |

|

1T |

50 |

5 |

20 |

75 |

50 |

35 |

65 |

132 |

14 |

M30X1.5 |

G3/8 |

G3/8 |

100 |

160 |

|

3T |

50 |

5 |

20 |

75 |

55 |

35 |

65 |

132 |

14 |

M30X1.5 |

G3/8 |

G3/8 |

100 |

160 |

|

5T |

50 |

5 |

20 |

75 |

55 |

35 |

87 |

155 |

17 |

M30X1.5 |

G3/8 |

G3/8 |

118 |

180 |

|

10T |

55 |

5 |

30 |

90 |

65 |

45 |

110 |

190 |

21 |

M39X2 |

G1/2 |

G3/8 |

145 |

225 |

|

13T |

55 |

5 |

30 |

90 |

65 |

45 |

110 |

190 |

21 |

M39X2 |

G1/2 |

G3/8 |

145 |

225 |

|

15T |

55 |

5 |

30 |

90 |

75 |

55 |

140 |

255 |

25 |

M48X2 |

G1/2 |

G3/8 |

200 |

305 |

|

20T |

55 |

5 |

30 |

90 |

75 |

60 |

140 |

255 |

25 |

M48X2 |

G1/2 |

G3/8 |

200 |

305 |