L Series high quality air source treatment unit pneumatic automatic oil lubricator for air

Product Description

1.High quality materials: The L series air source treatment device is made of high-quality materials to ensure its durability and long lifespan. These materials can withstand high pressure and high temperature environments and are suitable for various industrial applications.

2.Pneumatic automatic oil lubricator: This device is equipped with a pneumatic automatic oil lubricator, which can automatically provide lubricating oil to components in the air system. This helps to reduce friction and wear, extending the service life of the system.

3.Efficient filtration: The L-series air source treatment device also includes an efficient filter, which can effectively remove particulate matter and moisture from the air. This helps to protect the internal components of the system from contamination and damage.

4.Stable air source output: This device can stably provide dry and clean air, ensuring the normal operation of pneumatic equipment. It can also adjust the air supply pressure to meet the needs of different equipment.

5.Easy to install and maintain: The L-series air source treatment device has a simple installation and maintenance process. They are usually equipped with detailed instructions and operating instructions, allowing users to easily carry out installation and maintenance work.

Technical Specification

|

Model |

L-200 |

L-300 |

L-400 |

|

Port Size |

G1/4 |

G3/8 |

G1/2 |

|

Working Media |

Compressed Air |

||

|

Max. Working Pressure |

1.2MPa |

||

|

Max. Proof Pressure |

1.6MPa |

||

|

Filter Precision |

40 μ m(Normal)or 5 μ m(Customized) |

||

|

Rated Flow |

1000L/min |

2000L/min |

2600L/min |

|

Min. Fogging Flow |

3L/min |

6L/min |

6L/min |

|

Water Cup Capacity |

22ml |

43ml |

43ml |

|

Suggested Lubricating Oil |

Oil ISO VG32 or equivalent |

||

|

Ambient Temperature |

5-60℃ |

||

|

Fixing Mode |

Tube Installation or Bracket Installation |

||

|

Material |

Body: Zinc alloy; Cup: PC; Protective Cover:Aluminum alloy |

||

|

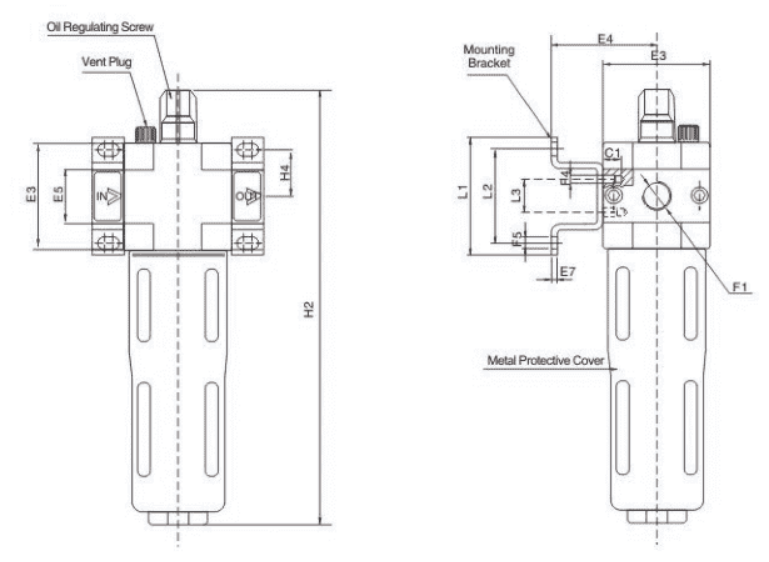

Model |

E3 |

E4 |

E5 |

E7 |

F1 |

F4 |

F5φ |

L1 |

L2 |

L3 |

H2 |

H4 |

H5 |

|

L-200 |

40 |

39 |

20 |

2 |

G1/4 |

M4 |

4.5 |

44 |

35 |

11 |

169 |

17.5 |

20 |

|

L-300 |

55 |

47 |

32 |

3 |

G3/8 |

M5 |

5.5 |

71 |

60 |

22 |

206 |

24.5 |

32 |

|

L-400 |

55 |

47 |

32 |

3 |

G1/2 |

M5 |

5.5 |

71 |

60 |

22 |

206 |

24.5 |

32 |