CQ2 series pneumatic compact air cylinder

Product Description

These cylinders can generate thrust by transferring gas to the piston cavity of the cylinder, and transmit the thrust to other mechanical parts through the piston rod of the cylinder. They are widely used in automatic production lines, machinery manufacturing, packaging equipment, printing equipment and other fields.

CQ2 series cylinders have good stability and repeatability, and can achieve accurate position control and fast action response. They can achieve different speed and force by adjusting the pressure and flow in the cylinder.

Technical Specification

|

Bore Size(mm) |

12 |

16 |

20 |

25 |

32 |

40 |

50 |

63 |

80 |

100 |

|

Acting Mode |

Double Acting |

|||||||||

|

Working Media |

Cleaned Air |

|||||||||

|

Working Pressure |

0.1-0.9Mpa(kaf/square centimeter) |

|||||||||

|

Proof Pressure |

1.35Mpa(kaf/square centimeter) |

|||||||||

|

Working Temperature |

-5~70℃ |

|||||||||

|

Buffering Mode |

Rubber Cushion |

|||||||||

|

Port Size |

M5 |

1/8 |

1/4 |

3/8 |

||||||

|

Body Material |

Aluminum Alloy |

|||||||||

|

Mode |

16 |

20 |

25 |

32 |

40 |

50 |

63 |

80 |

100 |

|

Sensor Switch |

D-A93 |

||||||||

|

Bore Size(mm) |

Standard Stroke(mm) |

Max Stroke(mm) |

Allowable Stroke(mm) |

|||||||||

|

12 |

5 |

10 |

15 |

20 |

25 |

30 |

|

|

|

|

50 |

60 |

|

16 |

5 |

10 |

15 |

20 |

25 |

30 |

|

|

|

|

50 |

60 |

|

20 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

90 |

|

25 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

90 |

|

32 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

40 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

50 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

63 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

80 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

100 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

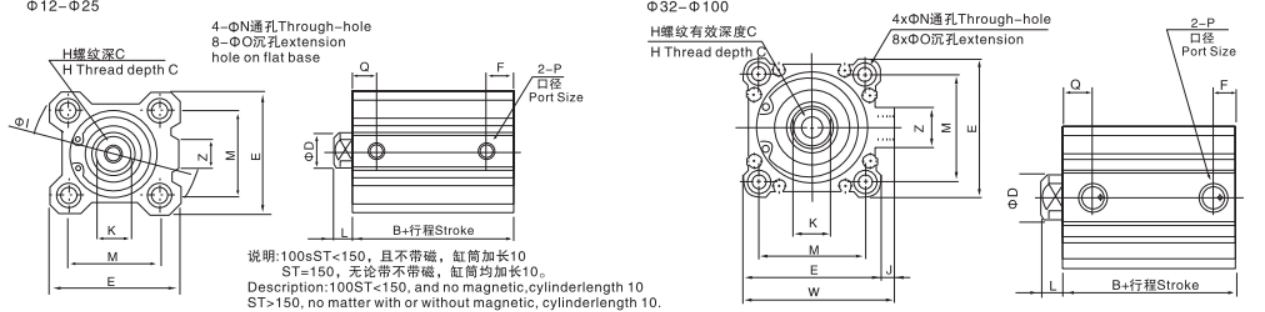

Bore Size(mm) |

B |

ΦD |

E |

F |

H |

C |

I |

J |

K |

L |

M |

ΦN |

ΦO |

P |

Q |

W |

Z |

|

|

Magnet type |

Standard type |

|||||||||||||||||

|

12 |

27 |

17 |

6 |

25 |

5 |

M3X0.5 |

6 |

32 |

- |

5 |

3.5 |

15.5 |

3.5 |

6.5depth3.5 |

M5X0.8 |

7.5 |

- |

- |

|

16 |

28.5 |

18.5 |

8 |

29 |

5.5 |

M4X0.7 |

8 |

38 |

- |

6 |

3.5 |

20 |

3.5 |

6.5depth3.5 |

M5X0.8 |

8 |

- |

10 |

|

20 |

29.5 |

19.5 |

10 |

36 |

5.5 |

M5X0.8 |

10 |

47 |

- |

8 |

4.5 |

25.5 |

5.5 |

9depth7 |

M5X0.8 |

9 |

- |

10 |

|

25 |

32.5 |

22.5 |

12 |

40 |

5.5 |

M6X1.0 |

12 |

52 |

- |

10 |

5 |

28 |

5.5 |

9depth7 |

M5X0.8 |

11 |

- |

10 |

|

32 |

33 |

23 |

16 |

45 |

9.5 |

M8X1.25 |

13 |

- |

4.5 |

14 |

7 |

34 |

5.5 |

9depth7 |

G1/8 |

10.5 |

49.5 |

14 |

|

40 |

39.5 |

29.5 |

16 |

52 |

8 |

M8X1.25 |

13 |

- |

5 |

14 |

7 |

40 |

5.5 |

9depth7 |

G1/8 |

11 |

57 |

15 |

|

50 |

40.5 |

30.5 |

20 |

64 |

10.5 |

M10X1.5 |

15 |

- |

7 |

17 |

8 |

50 |

6.6 |

11depth3 |

G1/4 |

10.5 |

71 |

19 |

|

63 |

46 |

36 |

20 |

77 |

10.5 |

M10X1.5 |

15 |

- |

7 |

17 |

8 |

60 |

9 |

14depth10.5 |

G1/4 |

15 |

84 |

19 |

|

80 |

53.5 |

43.5 |

25 |

98 |

12.5 |

M16X2.0 |

20 |

- |

6 |

22 |

10 |

77 |

11 |

17.5depth13.5 |

G3/8 |

13 |

104 |

25 |

|

100 |

63 |

53 |

30 |

117 |

13 |

M20X2.5 |

27 |

- |

6.5 |

27 |

12 |

94 |

11 |

17.5depth13.5 |

G3/8 |

17 |

123.5 |

25 |

|

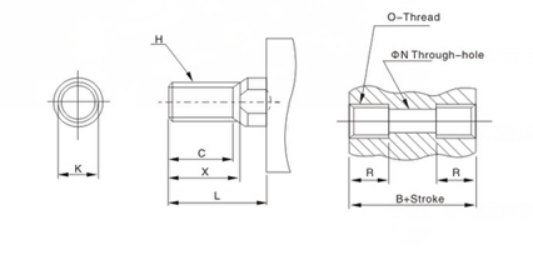

Bore Size(mm) |

C |

X |

H |

L |

O1 |

R |

|

12 |

9 |

10.5 |

M5X0.8 |

14 |

M4X0.7 |

7 |

|

16 |

10 |

12 |

M6X1.0 |

15.5 |

M7X0.7 |

7 |

|

20 |

13 |

14 |

M8X1.25 |

18.5 |

M6X1.0 |

10 |

|

25 |

15 |

17.5 |

M10X1.25 |

22.5 |

M6X1.0 |

10 |

|

32 |

20.5 |

23.5 |

M14X1.5 |

28.5 |

M6X1.0 |

10 |

|

40 |

20.5 |

23.5 |

M14X1.5 |

28.5 |

M6X1.0 |

10 |

|

50 |

26 |

28.5 |

M18X1.5 |

33.8 |

M8X1.25 |

14 |

|

63 |

26 |

28.5 |

M18X1.5 |

33.5 |

M10X1.5 |

18 |

|

80 |

32.5 |

35.5 |

M22X1.5 |

43.5 |

M12X1.75 |

22 |

|

1002 |

32.5 |

35.5 |

M26X1.5 |

43.5 |

M12X1.75 |

22 |