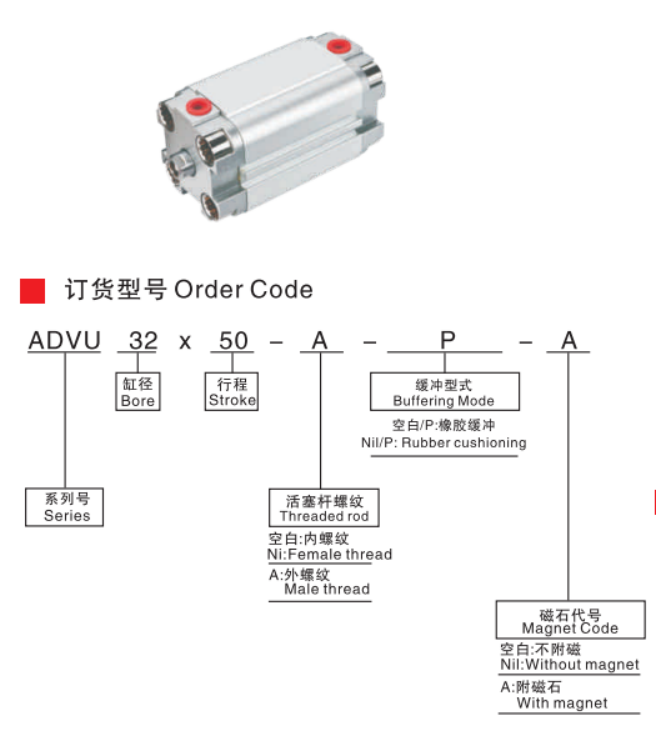

ADVU Series aluminum alloy acting compact type pneumatic standard compact air cylinder

Product Description

Advu series cylinders are of standard compact design, simple and compact structure, and easy to install and maintain. It has the characteristics of high precision and high reliability, and can work stably in various harsh environments.

The thrust range of this series of cylinders is wide, and the appropriate model can be selected according to different application requirements. It has a wide range of working pressure and temperature, and can meet the needs of various industrial fields.

Advu series cylinders have the characteristics of long life, low noise and low energy consumption, which can improve production efficiency and reduce energy consumption. It is widely used in machinery manufacturing, automobile manufacturing, electronic equipment and other fields, and provides strong support for the automatic production of various industries.

Technical Specification

|

Bore Size(mm) |

12 |

16 |

20 |

25 |

32 |

40 |

50 |

63 |

80 |

100 |

|

Acting Mode |

Double Acting |

|||||||||

|

Working Media |

Cleaned Air |

|||||||||

|

Working Pressure |

0.1~0.9Mpa(kgf/cm²) |

|||||||||

|

Proof Pressure |

1.35Mpa(13.5kgf/cm²) |

|||||||||

|

Working Temperature |

-5~70℃ |

|||||||||

|

Buffering Mode |

Rubber cushion |

|||||||||

|

Port Size |

M5 |

1/8 |

1/4 |

|||||||

|

Body Material |

Aluminum Alloy |

|||||||||

|

Mode/Bore Size |

12 |

16 |

20 |

25 |

32 |

40 |

50 |

63 |

80 |

100 |

|

Sensor Switch |

CS1-M |

|||||||||

Stroke Of Cylinder

|

Bore Size(mm) |

Standard Stroke(mm) |

Max.Stroke (mm) |

Allowable Stroke (mm) |

|||||||||

|

12 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

50 |

60 |

|

16 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

50 |

60 |

|

20 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

90 |

|

25 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

80 |

90 |

|

32 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

40 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

50 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

63 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

80 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

|

100 |

5 |

10 |

15 |

20 |

25 |

30 |

35 |

40 |

45 |

50 |

130 |

150 |

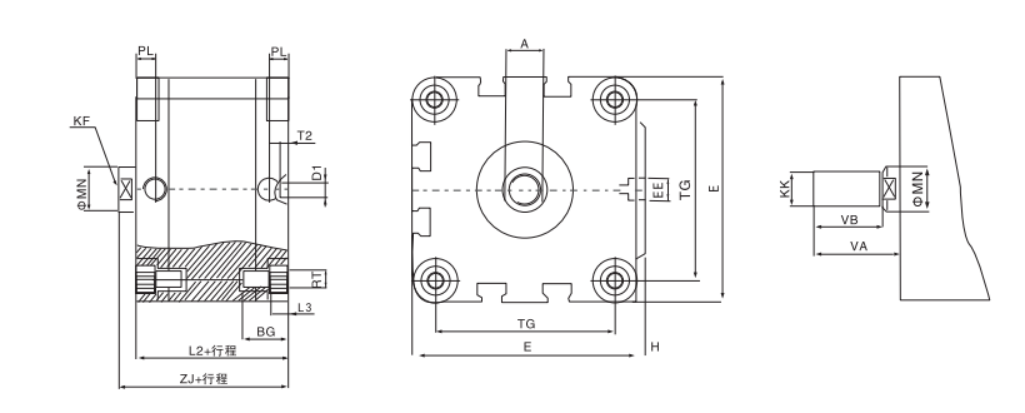

Dimension

|

Code Model |

A |

BG |

D1 |

E |

EE |

H |

L2 |

L3 |

MM |

PL |

RT |

T2 |

TG |

VA |

VB |

ZJ |

KK |

KF |

|

12 |

5 |

18.5 |

6 |

29 |

M5 |

1 |

38 |

3 |

6 |

8 |

M4 |

4 |

18 |

20.5 |

16 |

42.5 |

M6 |

M3 |

|

16 |

7 |

18.5 |

6 |

29 |

M5 |

1 |

38 |

3 |

8 |

8 |

M4 |

4 |

18 |

24.5 |

20 |

42.5 |

M8 |

M4 |

|

20 |

9 |

18.5 |

6 |

36 |

M5 |

1.5 |

39 |

4 |

10 |

8 |

M5 |

4 |

22 |

26.5 |

22 |

43.5 |

M10*1.25 25 |

M5 |

|

25 |

9 |

18.5 |

6 |

40 |

M5 |

1.5 |

41 |

4 |

10 |

8 |

M5 |

4 |

26 |

27.5 |

22 |

46.5 |

M10*1.25 25 |

M5 |

|

32 |

10 |

21.5 |

6 |

50 |

G1/8 |

2 |

44.5 |

5 |

12 |

8 |

M6 |

4 |

32 |

28 |

22 |

50.5 |

M10*1.25 25 |

M6 |

|

40 |

10 |

21.5 |

6 |

60 |

G1/8 |

2.5 |

46 |

5 |

12 |

8 |

M6 |

4 |

42 |

28.5 |

22 |

52.5 |

M10*1.25 25 |

M6 |

|

50 |

13 |

22 |

6 |

68 |

G1/8 |

3 |

48.5 |

6 |

16 |

8 |

M8 |

4 |

50 |

31.5 |

24 |

56 |

M12*1.25 25 |

M8 |

|

63 |

13 |

24.5 |

8 |

87 |

G1/8 |

4 |

50 |

8 |

16 |

8 |

M10 |

4 |

62 |

31.5 |

24 |

57.5 |

M12*1.25 25 |

M8 |

|

80 |

17 |

27.5 |

8 |

107 |

G1/8 |

4 |

56 |

8 |

20 |

8.5 |

M10 |

4 |

82 |

40 |

32 |

64 |

M16*1.5 |

M10 |

|

100 |

22 |

32.5 |

8 |

128 |

G1/4 |

5 |

66.5 |

8 |

25 |

10.5 |

M10 |

4 |

103 |

50 |

40 |

76.5 |

M |